目前公司主要开展的检测业务为电子电气产品、玩具及儿童用品、食品接触材料、化学检测、金属与合金元素成分分析、物理可靠性检测等理化检测。

At present, the company mainly carries out testing business for electronic and electrical products, toys and children’s products, textiles and related products, food contact materials chemical testing, metal and alloying element composition analysis, physical reliability testing and other physical and chemical testing.

食品接触材料是指用来包装、盛装以及加工、制作食品的一类材料及制品,与我们生活息息相关。食品接触材料可能含有数种有害化学物质,在与食品接触的过程中发生转移,直接或间接响着食品的安全。

近年来,食品接触材料引发的安全问题已经广泛引起人们的关注,欧盟及部分成员国、美国、中国、日本、韩国等地区针对食品级接触材料皆发布了法规或标准,并不断的进行完善和更新,出口到这些国家的食品接触材料都需要严格遵守这些法规的要求。

Food contact materials refer to a class of materials and products used for packaging, packaging, processing and production of food, and are closely related to our lives. Food contact materials may contain several harmful chemicals that are transferred during contact with food, directly or indirectly affecting food safety.

In recent years, the safety problems caused by food contact materials have been widely concerned, the European Union and some member states, the United States, China, Japan, South Korea and other regions have issued regulations or standards for food-grade contact materials, and continue to improve and update, food contact materials exported to these countries need to strictly comply with the requirements of these regulations.

| 欧洲区域 Europe region |

欧盟 EU |

框架法规:(EC)No. 1935/2004 Framework regulation:(EU)No. 1935/2004 |

|

特定指令:EU 10/2011,84/500/EEC(2005/31/EC)等 Legislation on specific material: EU10/2011, 84/500/EEC(2005/31/EC)etc. |

||

|

专项指令:(EU)No. 1895/2005环氧衍生物等 Directive on individual substances: directive on Epoxy Derivatives (EC)No. 1895/2005 etc. |

||

| 德国 Germany |

框架法规:LFGB第30,31和33条 Framework regulation: LFGB Chapter 30,31&33 |

|

|

BFR建议 BFR recommendation |

||

| 法国 France |

French Decret n°2007-766, French Decret n°2008-1469 | |

| DGCCRF 2004-64 | ||

| 意大利 Italy |

DPR No.777 23.8.82 | |

| Decreto Ministeriale del 21/03/1973 | ||

| 美国区域 USA region |

美国 USA |

食品、药品与化妆品法案 Food, Drug and Cosmetic Act 美国联邦法典FDA 21 Code of Federal Regulation (CFR) 170-189 |

| 符合性政策指南 Compliance Policy Guides, CPG 7117.05 & 06 & 07 | ||

| 行业协会标准 Industry Standards Association | ||

| 加州 California |

加州法案 California Proposition 65 | |

| 亚洲区域 Asian region |

中国 China |

《中华人民共和国食品安全法》 Food Safety Law of PRC |

|

各食品接触材料卫生标准,如GB 4806系列等 Health standard of food contact materials, such as GB 4806 etc. |

||

| 日本 Japan |

日本食品卫生法 Japan Food Sanitation Law | |

| 韩国 Korea |

韩国食品卫生法 Korea Food Sanitation Law |

特定迁移测试(重金属,※初级芳香胺,邻苯二甲酸酯,BPA等)

Specific migration test(Heavy metal、※PAA、Dimethyl phthalate、※BPA......)

特定迁移测试(重金属,※ 初级芳香胺,邻苯二甲酸酯)

Specific migration test(Heavy metal、※ PAA、Dimethyl phthalate)

邻苯二甲酸酯含量Dimethyl phthalate

成分分析 Component analysis

特定迁移测试(重金属,※ 初级芳香胺,邻苯二甲酸酯)

Specific migration test(Heavy metal、※ PAA、Dimethyl phthalate)

邻苯二甲酸酯含量 Dimethyl phthalate

有机挥发物 Organic vapour,※ 过氧化值 Peroxide value

双酚A残留 Bisphenol A vestigital

全面迁移量测试 Comprehensive migration volume test

特定迁移测试(重金属,※ 初级芳香胺,邻苯二甲酸酯)

Specific migration test(Heavy metal、※ PAA、Dimethyl phthalate)

成分分析 Component analysis

特定迁移测试(重金属,※ 初级芳香胺,邻苯二甲酸酯,※ PFOS)

Specific migration test(Heavy metal、※ PAA、Dimethyl phthalate、※ PFOS)

邻苯二甲酸酯含量 Dimethyl phthalate

特定迁移测试(重金属,※初级芳香胺,※单体)

Specific migration test(Heavy metal、※PAA、※Monomer)

※多环芳烃含量 Polycyclic aromatic hydrocarbons content

感官测试 Sensory organs

特定迁移测试(重金属,※初级芳香胺,邻苯二甲酸酯,甲醛)

Specific migration test(Heavy metal、※PAA、Dimethyl phthalate、Formaldehyde)

有机挥发物 Organic vapour,※过氧化值 Peroxide value

感官测试 Sensory organs

总含量(邻苯二甲酸酯,※多环芳烃,重金属,※有机锡)

Total content(Dimethyl phthalate、※Polycyclic aromatic hydrocarbons 、Heavy metal、※Organotin)

感官测试 Sensory organs

成分分析 Component analysis

感官测试 Sensory organs

特定迁移测试(重金属,※初级芳香胺,苯酚,甲醛,※三价铬,六价铬,※PFOS,※PFOA)

Specific migration test(Heavy metal、※PAA、Phenol、Formaldehyde、※Cr3+、Cr6+、※PFOS、※PFOA)

总含量(※多环芳烃,重金属)

Total content(※Polycyclic aromatic hydrocarbons 、Heavy metal)

感官测试 Sensory organs

高锰酸钾消耗量 Potassium permanganate consumption

全面迁移量测试 Comprehensive migration volume test

脱色试验 Decolorization test

特定单体迁移测试 Specific cell migration tests

铅镉溶出 Lead and cadmium release

镀银餐具 Silver-plated tableware

铅溶出 Lead release

铅镉溶出 Lead and cadmium release

Internal parts of ceramic and glass containers in contact with food

铅镉溶出

Lead and cadmium release

陶瓷及玻璃容器外部装饰部分

Ceramic and glass container exterior decoration parts

铅镉溶出

Lead and cadmium release

| 美国(联邦法典)第二十一部 US FDA 21 CFR DATABASE | ||

| 聚丙烯PP/聚乙烯PE |

提取物(正己烷,二甲苯)、熔点、密度 Extract (N-hexane, Xylene), Melting point, Density |

21 CFR 177.1520 |

| 橡胶/硅胶 Rubber/Silicone |

蒸发残渣(正己烷,水) Evaporities (N-hexane, Water) |

21 CFR 177.2600 |

| 涂层 Paintcoat |

蒸发残渣(水,正庚烷,8%乙醇) Evaporities (Water, N-heptane, 8%Ethyl alcohol) |

※21 CFR 177.300 |

| 聚苯乙烯 Polystyrene |

苯乙烯单体残留 Styrene monomer residue |

21 CFR 177.1640 |

| 尼龙 Nylon |

比重、熔点、溶解度、提取物 Specific gravity, Melting point, Solubility, Extract |

※21 CFR 177.1500 |

| 纸和纸板 Paper and board |

水、8%乙醇、50%乙醇和正庚烷中的提取物中氯仿可溶物 Chloroform soluble in extracts of Water, 8% Ethanol, 50% Ethanol and N-heptane |

※21 CFR 177.170 |

电子电器产品已是当今世界的一个主流消费品,已 深度渗入人们的生活当中。每年,电子电器垃圾的总量 都在成倍增加,电子电器垃圾的危害巨大。降低电子电器 产品中有毒有害物质的含量有利于回收利用及保护环境。

Electronic and electrical products have become a mainstream consumer goods in today’s world, and have gone deeply into people’s lives. Every year, the total amount of electronic and electrical waste is increasing exponentially, and the harm of electronic and electrical waste is huge. Reducing the content of toxic and harmful substances in electronic and electrical products is conducive to recycling and environmental protection.

检测项目 Test item

RoHS 2.0检测

※PoPs检测

※REACH附录17法规中限制物质测试

※高度关注物质(SVHC)

PoHS检测

※卤素(Halogen)检测

包装材料有毒有害物质检测Toxic and harmful substances in packaging materials

RoHS全称为电子电气设备中限制使用某些有害物质指令。 是欧盟议会和欧盟理事会于2003年1月通过,也称2002/95/EC指 令。RoHS于2005年、2011年先后进行了两次修订,升级为RoHS 2.0,原来测试的6项升级为10项,并规定过渡期。

RoHS stands for Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment. Directive 2002/95/EC was adopted by the European Parliament and the Council in January 2003. RoHS was revised twice in 2005 and 2011, upgraded to RoHS 2.0, and the original 6 tests were upgraded to 10, and a transition period was provided.

限制物质

Restricted substance

铅(Pb)

汞(Hg)

镉(Cd)

六价铬(Cr6+)

※多溴联苯(PBB)

※多溴二苯醚(PBDE)

邻苯二甲酸二(2-乙基己基)酯(DEHP)

邻苯二甲酸甲苯基丁酯(BBP)

邻苯二甲酸二丁基酯(DBP)

邻苯二甲酸二丁基酯(DBP)

限量要求

Limit requirement

1000ppm

1000ppm

100ppm

1000ppm

1000ppm

1000ppm

1000ppm

1000ppm

1000ppm

1000ppm

玩具通常是指设计或者提供给14岁以下儿童玩耍和使用产品。按材料可以分为毛绒玩具、塑胶玩具、 木质玩具和金属玩具等;按功能可以分为电动玩具、发声玩具、弹射玩具和水上玩具等;按用途可以分为 装扮类玩具、益智类玩具、体育类玩具和科教类玩具。

A toy is usually a product designed or provided for play and use by children under the age of 14. According to the material can be divided into plush toys, plastic toys, wooden toys and metal toys; According to the function can be divided into electric toys, sound toys, ejection toys and water toys; According to the use can be divided into dress-up toys, educational toys, sports toys and science and education toys.

| 测试项目 Item |

欧洲 EU |

美国 US |

加拿大 Canada |

澳大利亚/新西兰 Australia/New Zealand |

中国 China |

|---|---|---|---|---|---|

| 常规玩具需满足要求 General toys | |||||

| 物理和机械性能 Physical and mechanical |

EN 71-1 | ASTM F963, CPSC 16 CFR 1500.48,49, CPSC 16CFR 1501 | CCPSA SOR/2011-17 | AS/NZS 8124-1 | GB 6675 GB/T 5296.5 |

| 易燃性 Flammability |

EN 71-2 | ASTM F963, CPSC 16CFR 1500.44, CPSIA | CCPSA SOR/2011-17 | AS/NZS 8124-2 | GB 6675 |

| 化学特性 Chemical |

EN 71-3, EN 71-9 REACH | ASTM F963, CPSIA | CCPSA SOR/2011-17 | AS/NZS 8124-3 | GB 6675 GB 24613 GB 28482 |

| 毛绒玩具还需满足要求 Soft-filled toys | |||||

| 填充材料清洁度(目测) Cleanliness of stuffing material (Eye check) |

EN 71-1 | ASTM F963 | CCPSA SOR/2011-17 | AS/NZS 8124-1 | GB 6675 |

| 填充材料清洁度(化学分析) Cleanliness of stuffing material (Chemical analysis) |

— | Pennsylvania Regulation for Stuffing Cleanliness | — | — | — |

| 清洗性能 Cleaning and washing |

2009/48/EC, EN 71-1 | ASTM F963 | — | AS/NZS 8124-1 | GB 6675.2 |

| 电动玩具需满足要求 Electric toys | |||||

| 电气安全 Electrical safety |

EN 62115 | ASTM F963 Section 4.25, CPSC 16CFR 1505 | CCPSA SOR/2011-17, CSA C22.2 | IEC 62115 | GB 19865 |

| 遥控玩具需满足要求 Remote control toys | |||||

| 电磁兼容性 Electromagnetic compatibility |

EMC | FCC Part 15B | ICES-003 | AS/NZS CISPR 14.1 | — |

| 无线电发射频率 Radio-controlled frequency |

RED | FCC Part 15C | RSS-210, RSS-310 | AS/NZS 4268 | — |

可靠性就是产品在规定的条件下和规定的时间内,完成规 定功能的能力产品在设计、应用过程中,不断经受自身及外界 气候环境及机械环境的影响,而仍需要能够正常工作,这就需要 用试验设备对其进行验证。

Reliability is the ability of the product to complete the specified function under the specified conditions and within the specified time. In the process of design and application, the product constantly experiences the influence of its own and external climate environment and mechanical environment, and still needs to be able to work normally, which requires testing equipment to verify it.

1) 在研制阶段用以暴露试制产品各方面的缺陷,评价产品可靠性达到预定指标的情况;

2) 生产阶段为监控生产过程提供信息;

3) 对定型产品进行可靠性鉴定或验收;

4) 暴露和分析产品在不同环境和应力条件下的失效规律及有关的失效模式和失效机理;

5) 为改进产品可靠性,制定和改进可靠性试验方案,为用户选用产品提供依据。

1) In the development stage to expose the defects in all aspects of the trial product, evaluate the reliability

of the product to reach the predetermined index;

2) The production stage provides information for monitoring the production process;

3) Reliability evaluation or acceptance of stereotyped products;

4) Expose and analyze the failure law of the product under different environmental and stress conditions

and related failure modes and failure mechanisms;

5) In order to improve product reliability, develop and improve reliability test programs to provide a basis

for users to choose products.

卫浴产品测试

Sanitary product test

垃圾桶脚踏寿命测试

Trashcan pedal life test

跌落测试

Drop test

老化寿命测试

Aging life test

高低温测试

High-low temperature test

二次元尺寸项目测试

Quadratic dimensional project test

邵氏硬度测试

Shore hardness test

纸箱耐破强度测试

Carton bursting strength test

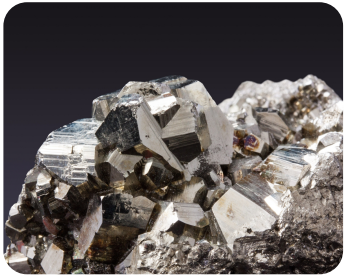

金属的选材不当或使用不当会造成材料的过早失效,严重的可能会发生重大事故。作为工业制造过程 中质量控制的一个关键环节,产品使用前对原材料、半成品或成品的检测过程就显得尤为重要。

Improper selection or use of metal can cause premature failure of the material, and serious accidents may occur. As a key link of quality control in the industrial manufacturing process, the testing process of raw materials, semi-finished products or finished products before the use of products is particularly important.

电感耦合等离子体发射光谱仪(ICP-OES) Inductively coupled plasma emission spectrometer

高频红外碳硫分析仪 Carbon sulfur analyyzer

X射线荧光光谱仪(XRF) X-ray Fluorescence spectrometer

硬度测试:洛氏硬度 Hardness test:Rockwell hardness

镀层厚度 Coating thickness

※附着力 Adhesion

中性盐雾试验 Neutral salt spray test

※循环盐雾测试 Cyclic salt spray test

※不锈钢晶间腐蚀试验 Stainless steel intergranular corrosion

※黄铜耐脱锌腐蚀试验 Dezincification resistance of copper alloys

| 锈蚀等级 Rating Rp |

缺陷面积(A%) Area of defects A (%) |

|---|---|

| 10 | 无缺陷 (No defects) |

| 9 | 0 < A ≤ 0.1 |

| 8 | 0.1 < A ≤ 0.25 |

| 7 | 0.25 < A ≤ 0.5 |

| 6 | 0.5 < A ≤ 1.0 |

| 5 | 1.0 < A ≤ 2.5 |

| 锈蚀等级 Rating Rp |

缺陷面积(A%) Area of defects A (%) |

|---|---|

| 4 | 2.5 < A ≤ 5.0 |

| 3 | 5.0 < A ≤ 10 |

| 2 | 10 < A ≤ 25 |

| 1 | 25 < A ≤ 50 |

| 0 | 50 < A |

| – | – |